The Tokenized Factory: How Blockchain and 3D Printing Converge with Robotics

Introduction: A New Industrial Paradigm

Factories have always been a reflection of the technologies that shaped their era. The steam engine brought mechanization, electricity powered assembly lines, and computers enabled automation. Today, we stand at the edge of the Tokenized Factory—a digital-first production system where blockchain, 3D printing, and robotics merge to create a more efficient, transparent, and adaptive manufacturing ecosystem.

This isn’t just Industry 4.0—it’s Industry Tokenized. By linking physical manufacturing with digital ledgers, we’re unlocking a new economic model where data, designs, and machines interact in real time to produce goods faster, cheaper, and more securely than ever before.

Top 10 Emerging Technologies Changing the World | AI, Robotics, Blockchain, 3D Printing & More

Part I: Blockchain as the Digital Backbone

At the heart of the tokenized factory is blockchain technology. Unlike traditional databases, blockchain provides an immutable, transparent ledger—perfect for global manufacturing networks where trust is critical.

Key Functions of Blockchain in Manufacturing

-

Design Tokenization

-

Every 3D model or design file can be turned into a digital token.

-

Creators receive royalties whenever their design is printed anywhere in the world.

-

Intellectual property is safeguarded through smart contracts.

-

-

Supply Chain Traceability

-

Blockchain records each step of the production process—from raw material sourcing to final assembly.

-

Consumers and regulators can verify authenticity and sustainability.

-

-

Payment and Settlement

-

Microtransactions between machines and suppliers happen instantly via crypto payments.

-

No need for banks, middlemen, or cross-border delays.

-

-

Machine-to-Machine (M2M) Commerce

-

Imagine a robotic 3D printer that automatically orders filament when it runs low.

-

Blockchain smart contracts execute these purchases seamlessly.

-

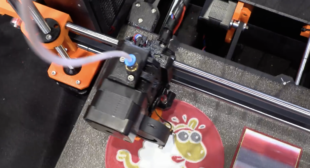

Part II: 3D Printing as the Engine of Customization

3D printing, or additive manufacturing, is the perfect partner for blockchain. It thrives in environments where customization, decentralization, and rapid iteration are key.

Why 3D Printing Fits the Tokenized Model

-

Distributed Manufacturing: Instead of shipping parts across the world, designs can be sent digitally and printed locally.

-

On-Demand Production: Goods are made when needed, reducing inventory costs.

-

Personalization at Scale: Blockchain ensures design rights, while 3D printing delivers one-of-a-kind products tailored to consumers.

Example: Aerospace & Automotive

-

Airbus could tokenize component designs, license them on blockchain, and enable certified suppliers worldwide to print parts.

-

Car companies could offer blockchain-secured 3D-printed accessories directly to customers, cutting out aftermarket risks.

Part III: Robotics as the Muscle of the Factory

While 3D printing creates the parts, robotics provides the automation muscle needed to scale the tokenized factory.

Roles of Robotics in the Tokenized Factory

-

Autonomous Production

-

Robotic arms manage multiple printers, swap materials, and perform post-processing tasks.

-

-

Quality Assurance

-

AI-powered robots inspect each layer in real time, reducing defective prints.

-

-

Logistics & Distribution

-

Automated guided vehicles (AGVs) transport raw materials and finished goods.

-

-

Integration with Blockchain

-

Robots confirm task completion on-chain, creating an auditable trail of accountability.

-

Case Study: Construction Robotics

3D printing robots are already building homes in the U.S. and Europe. Add blockchain contracts, and you could order a tokenized home model, have a robot print it locally, and log every step for legal and financial transparency.

Part IV: The Synergy of AI, Blockchain, Robotics & 3D Printing

The true magic happens when these technologies converge:

-

AI analyzes design and production data.

-

Blockchain secures intellectual property, payments, and supply chains.

-

3D Printing produces customized parts on demand.

-

Robotics automates manufacturing and logistics.

Together, they create a self-learning, self-financing, and self-managing factory.

Part V: Opportunities and Challenges

Opportunities

-

Global Design Economy: Designers can sell tokenized blueprints globally, earning royalties without shipping costs.

-

Sustainability: Localized 3D printing reduces carbon emissions from transport.

-

Faster Innovation: AI + blockchain streamline prototyping, approvals, and scaling.

Challenges

-

Standards & Regulation: Governments must adapt to new IP and safety frameworks.

-

Cybersecurity Risks: Tokenized design files must be protected from hacks.

-

High Upfront Costs: Robotics and industrial 3D printers remain expensive.

The Road Ahead

We are only scratching the surface of what the tokenized factory can achieve. In the near future:

-

Factories could operate as decentralized autonomous organizations (DAOs).

-

Consumers may hold tokens that let them vote on new product lines.

-

Designers could stream revenue from every print worldwide—just like musicians earn royalties from streaming.

The next industrial revolution won’t just be about machines—it will be about how value flows across digital and physical worlds.

Conclusion: The Factory of the Future Is Tokenized

Blockchain, 3D printing, and robotics are not separate technologies—they are the trinity of the next industrial age. Together, they will enable factories that are not only automated, but also transparent, decentralized, and economically inclusive.

The tokenized factory is more than a vision—it’s already emerging. Those who adopt it early will not just manufacture products; they’ll manufacture the future.

Comments